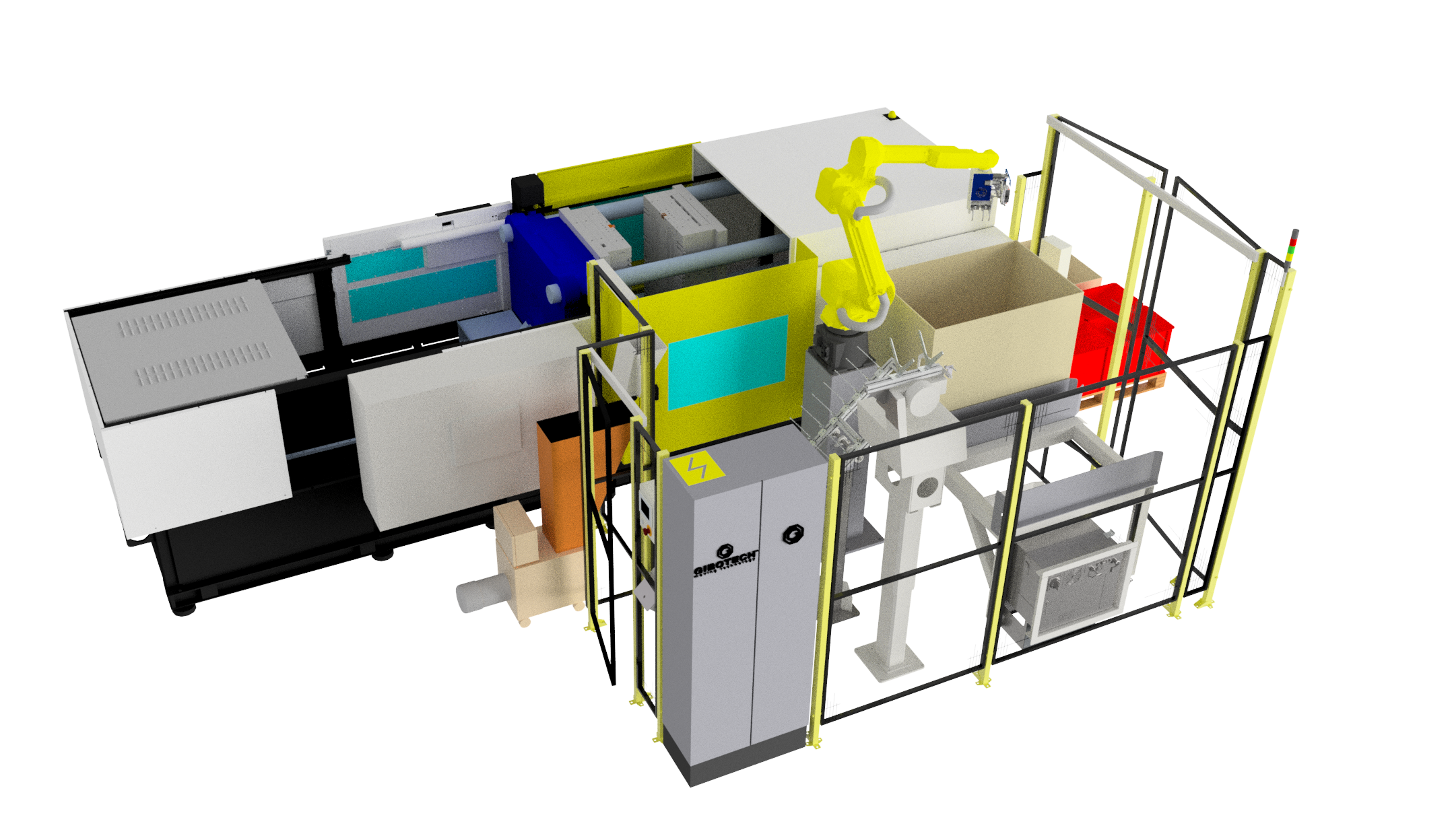

GiboMachineTending

Robot for

bundling

GiboSmartSolutions til maskinbetjening er baseret på

kendt teknologi og erfaringer fra tidligere projekter.

Løsningen tilbydes som en færdig turnkey løsning inden for rammerne beskrevet på bagsiden og kan nemt

tilpasses kundespecifikke krav efter behov.

Robot

Fanuc, Kuka

Software

Unique GibSoft software

Gripper

Customized for specific items

Solution

Can be integrated with other manufacturers of injection molding machines

Installation

Incl. Installation, commissioning and

training

Advantages

• Well-known technology tailored to your production

• 100% automated production line

• Better use of topics for increased efficiency

• Higher and more consistent quality of the finished product

• Fewer faulty items for less waste

• Higher throughput for increased productivity

• Releases employees for other tasks

• Improved competitiveness and greater employee satisfaction

Solution

• 1 Fanuc M20iA/12L, 6‑axis robot – On raised socket

• 1 specially designed gripper tool

• 1 strapping device

• 1 chute for test pieces

• 1 fixture for bundling items before strapping

• 1 customer-designed HMI touch panel with related user interface

• Interface – for communication between robot and moulding machine

• Complete safety solution

• Electrical cabinet and all necessary electrical components

• Electrical/pneumatic components for action items

• Gibsoft software package, automatic production, monitoring, etc.

• Installation and commissioning of installations at Gibotech A/S with FAT test

• Installation and commissioning of installations at the customer with SAT test

• Complete documentation package incl. CE

Functionality

100% automated production line for the production of injection moulded parts.

1 robot operates the injection moulding machine and handles the items throughout the process ranging from cutting waste, bundling of items, strapping of items to finally packing in boxes on pallets.