GiboSmartSolutions

GiboWeld

Compact

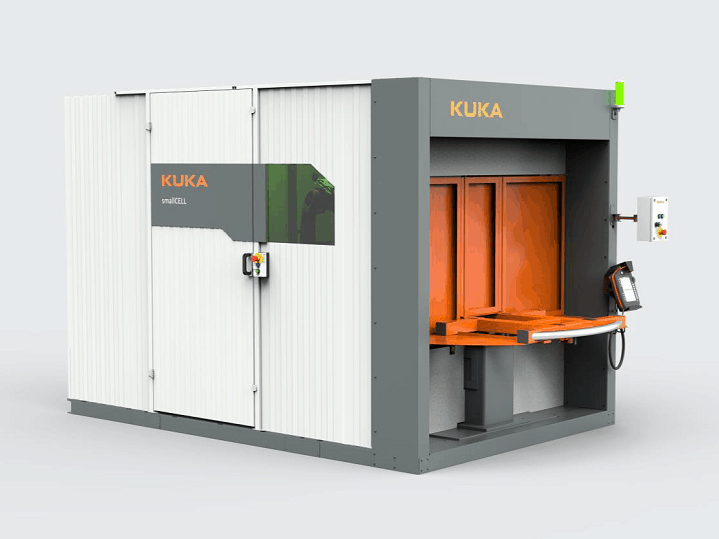

Gibotechs løsning til automatiseret svejsning. GiboWeld Compact er baseret på kendt teknologi og en KUKA-platform.

Løsningen tilbydes som en færdig turnkey løsning indenfor rammerne beskrevet på bagsiden og kan nemt tilpasses

kundespecifikke krav efter behov.

Robot

KUKA

Machine

Kemppi A7

Materials

Steel, aluminum, stainless steel

Mål

Width 2,200 mm, length 3,960 mm,

height 2,320 mm

Solution

The solution is delivered assembled and

ready to use

Advantages

• Compact mobile cell that saves space in the workshop

• Quick start welding tasks with simple simulation and off-line programming with pre-configured simulation modules

• High loading/unloading during the welding process

• The cell may be placed on a lorry and moved by truck if needed

• Prepared for remote support to reduce down time

• Closed cell for zero environmental impact in the workshop keeping sound, light and fumes away from the employees

Solution

• 1x completely closed welding cell on frame

o 2x doors

o Windows with welding glass

o Extraction in the ceiling

o Truck hangers

• 1x KR CYBERTECH nano KR 10 R1420 incl. controller and teach pendant

• 1x Gas-cooled Kemppi A7 350A power source

o Wirefeeder

o 5 meter welding gun

• Integrated software for steel, aluminum and stainless steel

• Abicor Binzel cleaning station

o Mechanical cleaning

o Spray

o Wire cutting and TCP reference

•1x manual turntable, payload 250kg, range 750x1200mm

• Software

o KUKA WebHMI

o KUKA ArcTech_Advanced

o KUKA TraccTCP

• Installation and commissioning at the customer’s premises

• Complete documentation package incl. CE documentation

• Robot and welding course for operators

Functionality

GiboWeld Compact is a compact welding solution for MIG/MAG welding of small parts in small or medium series. Welding can be performed in black steel, aluminum and stainless steel. With synergic or pulse ME arc. Despite the compact size of the cell it has a working area of 750 x 1,200 mm.

The cell is particularly suitable for creating the first experiences of automated welding in the transition from manual welding. It is easy to install the cell in the production as it arrives as a finished package with all equipment

configured.

After the robot course and welding course, the operator is ready to develop new welding programs for the cell.

GiboWeld has the latest software and can be programmed offline from a PC during the welding process. This saves time and increases productivity compared to manual welding.

The GiboWeld Compact has a smart turntable with two workstations allowing you to prepare new items while the cell is welding. This ensures an efficient production flow with maximum arc time.

GiboWeld is CE certified and designed for zero environmental impact in the workshop keeping sound, light and fumes away from the employees